Multi-Location Inventory Revolution: From Manual Chaos to Intelligent Distribution

Quick commerce and e-commerce platforms manage inventory across hundreds of dark stores and regional facilities. Manual tracking creates headaches, wrong availability data, and costly stockouts. Here's how FilFlo transforms multi-location operations into intelligent, profitable systems.

The Multi-Location Challenge

Quick commerce platforms like Blinkit and Zepto manage inventory across 100+ dark stores per city. E-commerce giants track stock in regional warehouses across India. Manual tracking creates chaos, wrong data, and millions in losses.

A single stockout at a Mumbai dark store can cost ₹50,000 in lost sales per day. Multiply across locations and the impact is devastating.

The Multi-Location Nightmare: Why Manual Tracking Fails

Data Inconsistency

- • Excel sheets updated at different times

- • No real-time visibility across locations

- • Human errors in data entry

- • Conflicting availability information

Delayed Decision Making

- • PO delays due to unclear stock levels

- • Reactive instead of proactive ordering

- • No predictive insights

- • Emergency procurement at premium costs

Regional Inefficiencies

- • Overstocking in some locations

- • Understocking in high-demand areas

- • No inter-location transfer insights

- • Poor demand forecasting

Real-World Impact: The Numbers Don't Lie

FilFlo's Multi-Location Intelligence Platform

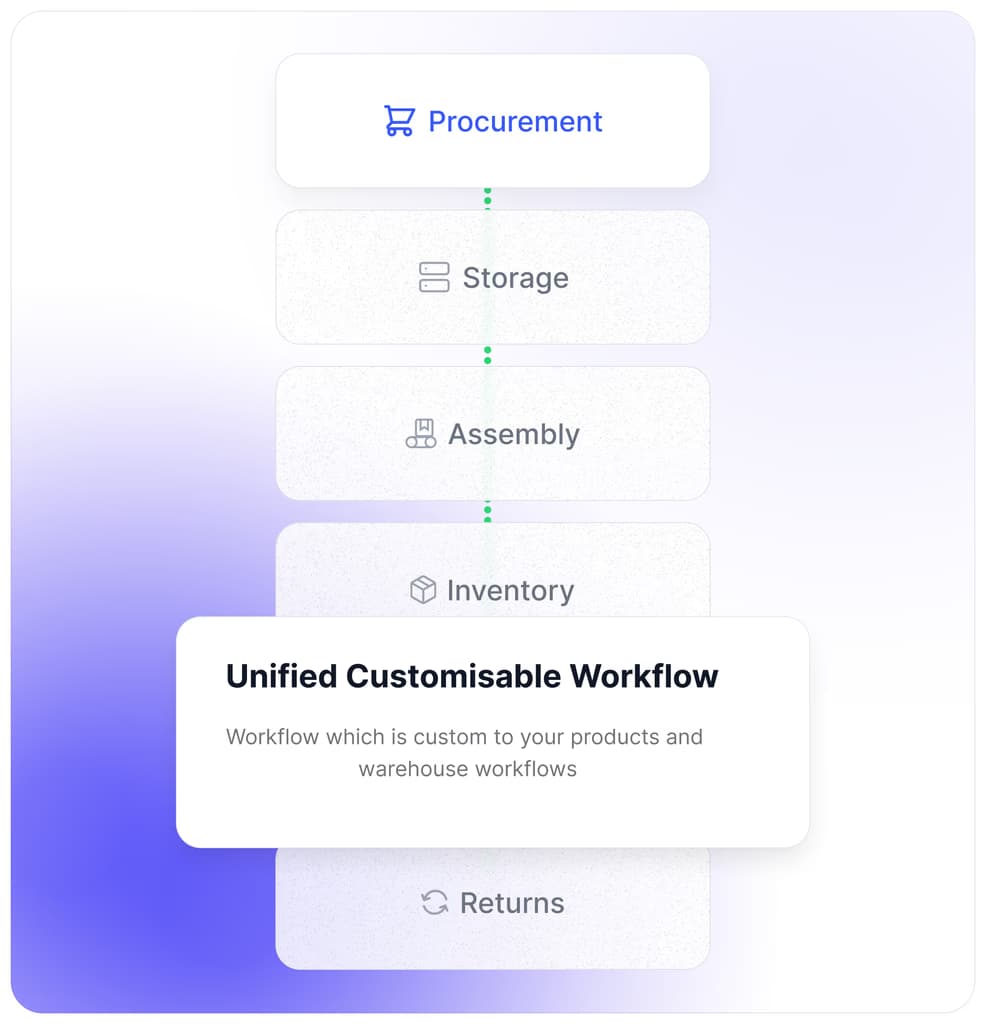

What We're Building:

A comprehensive inventory and procurement analytics platform that transforms complex multi-location supply chain data into actionable business intelligence through real-time insights and predictive analytics.

Real-time multi-location inventory dashboard showing live stock levels, demand patterns, and predictive alerts across all facilities.

For Business Decision Makers:

- Prevent Stockouts: Identify which products will run out before it happens

- Reduce Waste: Spot overstocked items tying up capital

- Optimize Cash Flow: Balance inventory investments with demand

- Improve Service: Ensure availability when customers need it

"Will we run out of stock?"

Predicts inventory depletion using Days on Hand (DOH) calculations

"Are our suppliers reliable?"

Tracks Purchase Order fulfillment rates and delivery performance

"Where are inefficiencies?"

Identifies bottlenecks in the supply chain process

"How much do delays cost?"

Calculates financial impact of supply chain issues

Core Features: Transforming Multi-Location Operations

Inventory Analytics

Real-time Stock Monitoring

Track inventory levels across multiple locations with live updates and instant synchronization.

Demand Forecasting

Predict future sales based on historical patterns and seasonal trends.

Critical Stock Alerts

Get warnings before items go out of stock with configurable thresholds.

Obsolete Stock Detection

Identify slow-moving inventory that's tying up capital unnecessarily.

Live inventory analytics showing stock levels, demand patterns, and predictive insights across all locations.

Comprehensive supplier performance tracking with delivery metrics and cost impact analysis.

Purchase Order Intelligence

Delivery Performance Tracking

Monitor how well suppliers meet their delivery commitments across all locations.

Fill Rate Analysis

Track what percentage of orders are fulfilled completely by each supplier.

Turn-Around Time (TAT) Tracking

Measure how long it takes from ordering to delivery for each location.

Cost Impact Analysis

Calculate financial losses from delays and inefficiencies in real-time.

Multi-Location Management

Regional Performance

Compare efficiency across different cities and facilities with detailed benchmarking.

Facility Optimization

Identify which locations perform best and understand the underlying factors.

Demand Distribution

Understand sales patterns across geographic regions and optimize accordingly.

Regional performance comparison showing efficiency metrics and optimization opportunities across all facilities.

Real-World Impact: How FilFlo Transforms Operations

Scenario 1: Preventing Stockouts

"The dashboard shows that Product X in Mumbai has only 3 days of inventory left, but the next delivery isn't scheduled for 7 days. The system alerts the team to expedite the order or transfer stock from another location."

Scenario 2: Supplier Performance

"Supplier ABC has a 65% fill rate (below the 80% threshold) and their deliveries are averaging 8 days late. The dashboard flags this supplier for performance review or replacement."

Scenario 3: Cost Optimization

"The Turn-Around Time analysis shows that delays in Delhi are costing ₹2.5 lakhs per month in lost sales. This data supports investment in faster logistics partners."

Scenario 4: Regional Insights

"Bangalore facilities are performing 15% better than other regions in inventory turnover. The dashboard helps identify best practices to replicate elsewhere."

Who Benefits: Transforming Every Role

Supply Chain Managers

- • Monitor supplier performance and delivery schedules

- • Identify bottlenecks and process improvements

- • Optimize inventory levels across locations

- • Make data-driven supplier decisions

Finance Teams

- • Track inventory investment and carrying costs

- • Measure financial impact of supply chain decisions

- • Forecast cash flow requirements for purchasing

- • Calculate ROI of operational improvements

Operations Teams

- • Ensure product availability for customer demand

- • Coordinate between warehouses and distribution centers

- • Plan for seasonal variations and demand spikes

- • Optimize inter-location transfers

Executive Leadership

- • Get high-level visibility into supply chain health

- • Make data-driven decisions about supplier relationships

- • Understand operational efficiency across organization

- • Drive strategic improvements based on insights

Technical Innovation Behind the Platform

Smart Data Processing

Automatically handles messy CSV uploads and data inconsistencies from multiple sources and formats.

Predictive Analytics

Uses historical patterns to forecast future trends and prevent stockouts before they happen.

Real-time Calculations

Processes thousands of data points instantly for live insights across all locations.

Mobile-Responsive Design

Access critical information on any device, anywhere - perfect for field operations.

The Bottom Line

This isn't just another reporting tool - it's an intelligent assistant that helps businesses make smarter supply chain decisions, reduce costs, and improve customer satisfaction by ensuring the right products are available at the right time and place.

For companies managing complex inventories across multiple locations, this dashboard transforms overwhelming data into clear, actionable insights that drive better business outcomes.

Ready to Transform Your Multi-Location Operations?

Stop losing money to manual tracking chaos. See how FilFlo's intelligent platform can revolutionize your multi-location inventory management in just 30 days.

Related Articles

How Predictive Analytics Can Prevent Stockouts Before They Happen

Discover how FilFlo's advanced analytics help businesses predict inventory depletion using real-time monitoring.

When Supplier ABC Became a ₹50 Lakh Problem

A comprehensive case study on how poor supplier performance impacts multi-location operations.